Complete Guide To Inflatable Boats.

Complete Guide To Inflatable Boats.

Introduction to inflatable boats:

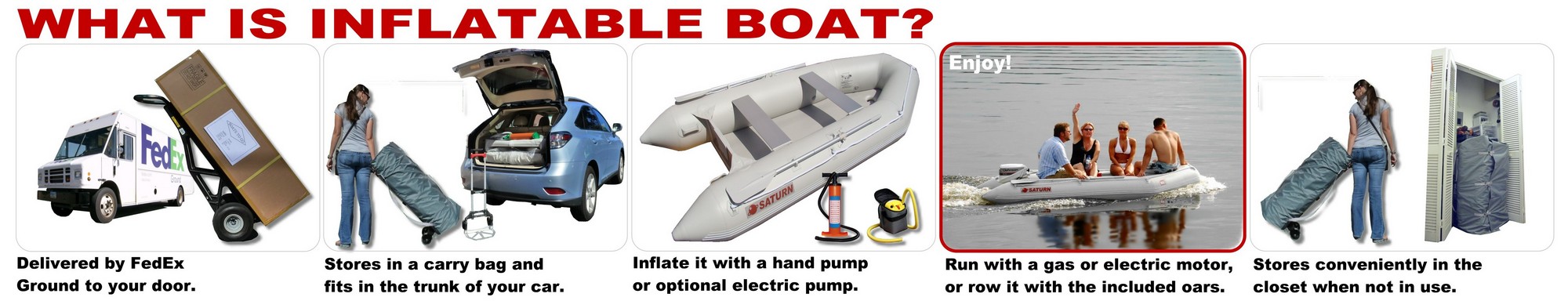

Inflatable boats in general, are ones of most seaworthy vessels, since they are air-filled, which offers maximum buoyancy. Surge in popularity of inflatable boats can be attributed to a number of reasons, including some inherent benefits of inflatables, such as their ability to deflate for storage for small spaces, their ability to be tied to ships without leaving marks on them, and the fact that inflatable boats are seaworthy vessels. Inflatables are capable of supporting up to ten times their own weight, can float if one of their tubes blows, are intrinsically stable, and provide on-the-water performance that can be tailored to suit almost any purpose. The popularity of inflatable boats is also due to the fact that the cost of the materials and labor used in their production has reduced, significantly lowering the financial commitment required to own and maintain one..jpg?1667330295236)

Of all the boats on the market, inflatable boats provide the best balance of storage, cost, durability, load capacity, capability, weight, and performance. The day a man buys his boat and the day he sells it are the two finest days of his life, unless it's an inflatable boat! When buying a boat, space availability and convenience are two crucial factors to take into account. Inflatables address both of these issues. Of all the boats on the market, inflatable boats provide the best balance of storage, cost, durability, load capacity, capability, weight, and performance. In comparison to other types of boats, inflatable boats are quite light. As a result, they are a perfect fit for any lifestyle, from the weekend warrior who lives in an apartment, to the globetrotter who lives on their yacht where space is at a premium. Inflatable boats can endure around ten years when maintained properly, or even longer with the necessary care and safeguards.

.jpg?1667330339601)

Everybody can use and enjoy the boat that is made possible by the combination of all these qualities., which makes them portable and simple to store.

OVERVIEW: inflatable boats are incredibly adaptable, there are a variety of inflatables available to suit different user requirements. Inflatables can be used for practically anything, from yacht tenders for sailboats to fishing boats for those who live in apartments. It's challenging to stay up to date with new technology and goods because the inflatable boat market is always expanding and changing. This article aims to instruct both inexperienced and seasoned boaters on the ins and outs of inflatable boats.

This educational article describes the various inflatable boat designs currently available, how they were created, their unique advantages and disadvantages, and the kinds of uses they are most suitable for. This guide will assist you in determining which inflatable boat style, motor options, and use scenarios are most appropriate for your requirements.

To help you understand how each component contributes to giving you the finest boating experience possible, this article will also discuss the numerous materials inflatable boats may be made of, the various building techniques utilized, and the various inflatable boat designs.

TYPES OF INFLATABLE BOATS:

There are numerous ways to classify inflatables, and the most of them will be explored in this article. The type of boat floor used is a frequent approach to distinguish between rival technologies.

1. The ROLL-UP floor is the most fundamental form of floor material that we shall discuss initially. Roll-up or slat floor inflatables are available in a wide variety of sizes, qualities, and materials, but frequently lack a keel. The roll-up flooring of these inflatables are convenient for storage and are often less expensive than more sophisticated inflatables, but they lack durability and rigidity. Roll-up floors are made up of a series of lateral slats with spaces between them; this restricts passenger movement and leaves the floor vulnerable to damage. Achilles, Mercury and West Marine are two prominent manufacturers of these boats. Saturn used to made that type of boats in a past.

These boats are utilized because they are portable and simple to put up. They are made to be compact, easily handled, and folded up for storage. Roll up floor boats are practical for quick ship-to-shore voyages, but they are inadequate for longer expeditions. Slatted floors, if broken, can swiftly harm the fabric, making certain portions of these boats less resilient and more prone to tears or leaks. The inflatable boats are made to be simple to put together and inflate. However, performance suffers when simplicity takes precedence.

Roll-up floors are made up of a series of lateral slats with spaces between them; this restricts passenger movement and leaves the floor vulnerable to damage. When on the water, these boats frequently lack a keel, which causes problems with directional stability, particularly when traversing choppy and stormy waves or when turning. The maximum speed that can be reached with this kind of boat is severely constrained by the floors, which are often unable to take off and are too flimsy to sustain a keel.

Roll-up boats are available in a wide range of designs, dimensions, and costs. The smallest roll-up inflatable without a keel is 4.8' long, $12–30 from Intex, and driven by oars. It can only carry one small kid. The Achilles LS4-RU is one of the bigger roll-up inflatables without a keel. This inflatable is 8'8" length, costing $1,300–1,400, may be propelled by a gas or electric outboard, and can hold up to 4 people.

2. The HARD FLOOR is one of the most common types of inflatable floors, which perform better while offering greater durability than roll-up options. Their V-shaped keel and heavier duty hard floor pieces made of aluminum or wood are responsible for this performance improvement. Achilles, Zodiac, Saturn Boats, Sea Eagle, Mercury, and West Marine are the leading manufacturers of boats in this category.

Inflatable boats with hard floors provide the most stability at speed because they have a lower center of gravity, support the keel better, and have better hull shapes. This gives the boat the confidence and stability to tackle choppy waters, large waves, other boats' wakes, and fast speeds.

Hard floor boats are often composed of higher quality materials and are designed to last, typically PVC or CSM (Hypalon), however TPU is occasionally used. Price increases coincide with improvements in both quality and durability. These inflatables are still easy to build up and deflate, but they do take a little more time and work.

Depending on the pump and the ease of the floor installation, an individual user with setup experience can usually set up one of these by themselves in around 10-15 minutes or less. Here is an example of floor installation at https://www.boatstogo.com/PlywoodFloor.asp

Hard floors serve as the backbone of inflatable boats and offer good structural stability. They must be installed before the keel and hull are fully inflated. Compared to air flooring or slat floors, these additional processes can increase the entire installation time by 5 minutes. The advantages far outweigh the extra setup time, which takes only approximately 10-15 minutes in total. You can travel faster, stay more stable, and manage big waves and wakes better with hard floors.

The additional weight that comes with a hard floor is a significant factor to take into account when making a purchasing decision. An equivalent air floor or roll-up boat will weigh between 15 and 25 percent less than a hard floor boat. Depending on the boat's overall size, the type of floor material utilized, and the total number of floor components, the exact weight gain will change. Aluminum is the most durable material and will be lighter than wooden floor, which may be dented, rotted and damaged more readily.

One of the most common types of inflatable floors are hard floors, which perform better while offering greater durability than roll-up options. Models in this category come in a wide range of sizes, measuring anything from 10 feet to 23 feet in length. Mercury makes the smallest hard floor boat. The Mercury 240 is a 7'3" PVC boat that costs between $900 and $1,000 and holds a maximum of three persons. The Zodiac Mil-Pro Heavy Duty Series is the largest boat. This boat is 23' long, composed of Hypalon, can accommodate 20 people, and it costs more than $34,000. Saturn makes boats with hard floors in range from 10' to 18'.

3. AIR FLOOR: With the advent of drop stitch materials, air floors have become more and more well-liked in recent years. In the past, air floors had an inflated bladder floor with I-Beam construction; however, these floors are less rigid and more prone to punctures than more recent drop stitch floors. Drop stitch floors provide a convenient combination of quality, mobility, and durability. Air floors roll up effortlessly for storage and are very light. These boats have an air floor, which makes them lighter while providing performance on par with boats with concrete floors.

Achilles, Zodiac, Saturn, Mercury, Sea Eagle, and West Marine are well-known companies that sell air floor inflatables. Although drop stitch fabrics are a new technology that not all inflatable producers have embraced, not all air floors are made equal. A classic bladder-style air floor, which offers little structural support for the hull, is still used by some manufacturers. These designs are less durable than drop stitch floor boats and are more prone to abrasion and puncture.

Because drop stitch materials have become more widely used in recent years, air floors have become more popular. Although air floors can be used for many of the same applications as hard floors, they do have significant restrictions. We will mainly concentrate on higher quality drop stitch floors since I-Beam air floors are antiquated and only provided by a few manufacturers. Air floors become nearly as rigid as hard floors while weighing less and taking up less storage space thanks to drop stitch floors, which are made to withstand high pressures, frequently inflated to 8–12 psi. This makes these inflatables very transportable and simple to store in small locations. Air floor inflatables work admirably in the water as well. Their inflatable keels offer them directional stability and enable them to take off swiftly. They can handle choppy water better than hard flooring, but because of their lighter weight and greater center of gravity, they can feel less stable at faster speeds. Despite being exceedingly rigid, the high-pressure air floor cannot keep the boat entirely rigid and allows some flex. They are therefore not the best boat for those who enjoy going fast or who frequently navigate choppy waters.

Hard floors and air floors are almost equally adaptable and have many of the same uses. The boats in this group are often constructed using PVC or Hypalon and adhere to the same standards as hard floor variants. The setup and tear down times for these boats are shortened because of the one-piece air floor, and they can typically be set up in less than 10 minutes. The gently padded floorboards increase passenger comfort, especially for their knees and feet when moving around the boat. An air floor might be a more pleasant solution for your family if children are kneeling or sitting on the floor while riding in choppy water. When working with rough or sharp objects, air-floored boats are not the best option. These flooring are made of PVC fabric, which means they are susceptible to tearing, chafing, and abrasion, all of which can cause long-term damage to the floor. Drop stitch floors are less durable than hard flooring and bladder air floors, but replacements are available from reliable manufacturers; if your boat's drop stitch floor needs to be replaced, get in touch with us. A new floor can be more expensive to buy than hard floors if the damage is beyond repair. The air floor of your boat may be impacted by the weather depending on where you want to use it; for example, if you place it in cold water, the air in the floor will condense and soften the floor. When the weather changes while the air floors are being used, they could also need to be topped off. Even while it shouldn't be a deal-breaker, you should consider this when picking the ideal inflatable for your particular usage.

4. RIBS: The acronym RIB, which stands for Rigid Inflatable Boat, is frequently used while looking for inflatable boats. These boats are a hybrid of an inflatable and a conventional fiberglass boat. They differ from the inflatables mentioned above in that they have solid contoured hulls. Although the boat now weighs more, it may perform better on the water. These boats are made by several well-known companies, including Zodiac, Achilles, Defender, Avon, and AB Inflatables. RIBs frequently have deep-V hulls, which enhance their performance on the water, let them to take off rapidly, and allow them to easily cut through chop and waves. They become even faster by having this type of hull, which also boosts the top speed. For enhanced buoyancy and the famed stability that inflatable boats provide, they nevertheless include tubes on the topside. Their hulls can be made of a variety of materials, including polyester, aluminum, and fiberglass.

This enables the employment of inflatable boats for a variety of purposes, such as Coast Guard missions, commercial or charter fishing operations, and more. However, a major loss in portability and a significant rise in cost come along with an improvement in performance.

The ability to roll up and stow the "inflatable" is lost when the hull is solid, increasing the boat's overall weight. This necessitates a huge storage space and limits the possibilities for transport to a trailer. RIBs range in price from $1,500 to $30,000, depending on the size and materials utilized.

The steering and throttle controls on a console make it considerably simpler to handle and steer the craft at high speeds. These console RIBs were created with the vessel's pilot in mind. The heavier and more powerful engine needed to propel the boat will depend on how big the RIB is. When compared to speed boats and other watercraft, these hybrid inflatable fiberglass boats have a high level of performance on the water.

The steering and throttle controls on a console make it considerably simpler to handle and steer the craft at high speeds. These console RIBs were created with the vessel's pilot in mind. The heavier and more powerful engine needed to propel the boat will depend on how big the RIB is. When compared to speed boats and other watercraft, these hybrid inflatable fiberglass boats have a high level of performance on the water. Because of this, they are the best options available in the commercial sector for fishing boats, military applications, applications for scientific research, and tenders for opulent super yachts.

The presence of a console on a RIB, which adds weight and moving elements that can break and necessitate pricey specialized repairs, takes up a lot of room and has several disadvantages. RIBs have a higher cost of ownership than completely inflatable boats since even anything as simple as a broken or damaged steering wire could leave you stranded. Additionally, the steering wheel can impair your ability to navigate your dinghy at slower speeds and restrict visibility. Last but not least, these installations may get quite pricey, starting at about $9,000 and going up to far over $75,000! For private usage, they come in sizes ranging from 8' to 24', and even larger ones for commercial use.

BOATS WITH KEELS: Roll up floor boats without a keel offer poor performance and are little more than an inflatable barge; having a keel considerably boosts a boat's performance, versatility, and value. An inflatable with a keel can readily take off and perform better on the water than one without one. This performance is unmatched by a Soft Tail or Roll-up inflatable. A boat's keels enable it to take off, slice through the water, and provide excellent handling and stable turning performance. Anyone going in an open ocean, attempting to get from point A to point B as rapidly as feasible, or seeking improved performance from their inflatable needs to know this.

This may be someone utilizing it as a tender to a family going on a short vacation. They provide the extraordinary performance anticipated from inflatable boats and are commonly seen on inflatable tenders and RIBs.

BOATS WITHOUT KEELS: Inflating and storing a boat is made simple for boats without keels. Without a keel, inflation and deflation times as well as initial cost may be shortened at the expense of performance and speed. When you are getting ready to use the inflatable or when you are done and ready to pack it up, you won't have to take extra time to inflate and deflate that air keel chamber. This speeds up the transition from land to water, but once on the water, it makes it more slower. Even though quick assembly is a positive, these cheaper inflatables have more drawbacks. Your range and speed are severely constrained if you can't readily board a plane or navigate chop. For applications involving brief, ship-to-shore voyages on flat water, these inflatables can still be helpful and worthwhile purchases, but frequently leave users wanting more.

There are a few distinct hull forms for inflatables on the market today, including the FLAT HULL. They come in flat, V, and Deep-V hull varieties. They were each created with a distinct purpose and functionality in mind. These can be produced from PVC or Hypalon, however although being less expensive, they perform poorly. Inflatables without a keel are known as flat hulls. These can be produced using PVC or CSM, however although being less expensive, they perform poorly. These inflatables can't cut through choppy water, get up on a plane to go at faster speeds, or maintain directional stability without a keel. Boats with flat hulls can't go at greater speeds and aren't advised for open ocean navigation. These hull designs make excellent inflatable tenders for short tendering trips or quick fishing excursions on flat water. They are perfect for moving short distances at slower speeds.

V-HULL: Boats with a V-hull are inflatables that are made of PVC or Hypalon and have an inflatable keel. To aid the high pressure keel in cutting through the water, these boats include high pressure air or hardwood floors. These boats have higher top speeds, directional stability, and can cut through wakes and waves more easily than flat hulls because to their inflatable V-hull design. Boats with these hulls are incredibly stable even though they have this added performance. V-hull boats are more expensive than boats without a keel, however this is justified because they provide excellent performance at a low cost. These characteristics make these hulls an excellent option for a variety of uses; they can be used as tenders, family runabouts, fishing boats, diving boats, crab boats, wildlife photography boats, and more. Whatever the application, a V-hull design offers the optimum balance of cost, performance, and size and won't leave you wanting more performance. All Saturn inflatable boats employ this type of hull, which is the most typical for inflatables.

DEEP V-HULL: RIBs have deep-V hulls, which can be made of fiberglass or metal. These hull types will be the most expensive. In contrast to an inflatable keel, these hull styles can reach deeper into the water. This will give you more stability, control, and the ability to slice through the waves like a knife.

Aluminum deep-V hulls will be more lightweight, strong, and repairable than fiberglass ones. Aluminum hulls are thought to be less stable than fiberglass, nevertheless. Fiberglass hulls can be exceedingly expensive and challenging to repair if they are damaged. These boats will float higher because of the deep-V hull shape. As a result, they are less stable and more likely to tilt or rock in the presence of wind. For someone who wants to maximize performance without leaving the inflatable category, this is the perfect hull.

INFALTABLE BOAT TUBE SIZE: Depending on how you intend to use your inflatable, tube size may be crucial. The capacity and stability of the boat will decrease as the tube diameter decreases, whereas larger tubes have higher capacities and are more stable. If you need a boat that will function in the open ocean or if there are youngsters on board, this is significant with inflatables. Smaller tubes offer more bow spray and provide for a less comfortable ride when traveling at fast speeds through choppy waters. It becomes less stable and buoyant overall, which causes a choppy ride. A safer and more comfortable ride for the driver and passengers is produced by larger tube diameter.+

Larger diameter tubes work better in any environment, but their cost rises in tandem with their improved safety and comfort. Large tubes can be handy and useful in practically any situation; it is better to have them on board your boat than to wish you had them. The only drawbacks of larger tubes are an increase in cost and a reduction in interior volume of the inflatable. You will have fewer options for what you can fit if the boat needs additional room. The added buoyancy that the tubes offer, however, makes them an excellent alternative if you have heavier objects that you need to tender or bring on your journey.

The capacity and stability of the boat will decrease as the tube diameter decreases, whereas larger tubes have higher capacities and are more stable.

CONSTRUCTION OF INFLATABLE BOATS:

WELDING AND GLUE: The necessary building technique for an inflatable boat is frequently determined by the type of material utilized. PVC and TPU boats can be glued or heat welded, whereas CSM (Hypalon) boats can only be put together with glue and strong adhesives. Inflatables are made of forms of precisely cut fabric that are sewn together at specific points to form seams that connect the tubes and other boat components. How a boat is manufactured is largely determined by the kind of material the factory is utilizing, their capacity to invest in the newest technology, and other considerations.

ADHESIVES: The original technique used for putting together inflatable boats was glue, and it is still commonly used today. This method is the only one that can be used with any material, it works well, and it is the only one that can be used with CSM inflatables. One must score the material first, then apply glue to both fabric surfaces for the glue to form a solid bond it must penetrate into the fabric pores. The glue doesn't adequately set and bond the materials together until the two portions are tightly rolled together. This additional manual effort contributes to the CSM inflatable's overall cost rise.

Assembly of inflatable boat using heat welding method:

A mechanical bond can be created between PVC and TPU seams by using an adhesive that is compatible with these materials. The adhesive penetrates the material's pores when it is liquid, and when it dries, it forges a solid bond.

The fact that the quality and strength of glued seams depend on the adhesive's performance and the time required to construct it is a significant disadvantage. The glue's tensile strength will gradually deteriorate over time as a result of UV exposure and harsh weather. It should be remembered that boat materials typically deteriorate before adhesives do.

HIGH FREQUENCY WELDING: Hot air welding was developed from high frequency welding, also known as radio frequency welding, which has been around since the 1940s. An electromagnetic field is used in this kind of weld to fuse two textiles together. Two textiles are clamped between two flat metal electrodes, and a high frequency voltage is applied. The resultant extreme heat causes the fabric molecules to vibrate at high rates, melting and bonding the fabric as the two electrodes press against it. High frequency welding heats the cloth from the inside out, as opposed to only the surface. This procedure functions like a microwave and just takes a few seconds all in all.

These machines are severely limited in their ability to produce three-dimensional items when compared to more sophisticated hot air welding, and their setup is far more time-consuming than other methods. The lengths that high frequency machines can produce at one time are similarly constrained, and the need for numerous machines of various sizes to produce a single item drives up manufacturing costs dramatically. Multiple machines and a longer setup time raise the price of the product for the consumer. Additionally, compared to hot air welded seams, these seams are weaker and less aesthetically pleasant. There is a clear reason hot air welding, which is more effective, long-lasting, and economical, is replacing this older kind of welding.

HOT AIR WELDING: Hot air welding is the most current development in inflatable construction. This entails heating the material on two sides to a high temperature until it starts to melt. A machine then tightly rolls the two sides together, joining the two distinct PVC sheets to form a strong and dependable seal. Due to the structure of CSM, welding cannot be used to bind the materials together; only PVC and TPU may employ this technique.

The construction of inflatable boats is made more efficient by the heat welding method. By doing away with adhesives, PVC boats' UV resistance is increased, which reduces flaws and lowers the cost to the user. Heat welding creates a seam that is superior to glued seams in terms of strength. Hot air welded seams have the lowest overall fault rate of all inflatable seams, resulting in a better product at a reduced price. We are delighted to offer top-notch craftsmanship on all of our inflatable boats at Saturn, which is why we heat weld and use only the best German-made adhesives.

While there are just a few options for seam sealing, such as adhesive or welding, there are numerous ways to put an inflatable's seams together. While some generate a robust seam construction and are visually appealing, others are unattractive and less long-lasting. Boat seams are typically built using one of six main techniques: heat welding, reinforcing lap seams, heat welding simple laps, double reinforcing lap seams, and double reinforcing butt seams.

The two-seam constructions that use heat welding for bonding are the Heat-Welded Flange and the Heat-Welded Simple Lap. Only PVC and TPU materials are used with this technique.

1) Cheap play boats and pool floats are the main uses for heat-welded flange. Generally speaking, it is made of weak, low-quality materials. The flange protrudes and is vulnerable to wear from frequently hooking on objects; over time, this abuse may result in failure.

2) The ideal heat welding technique is heat-welded simple laps. A very effective and robust bond with the material is produced by simply overlaying the fabric. Without a flange, the seam has a significantly longer lifespan because it is used less frequently.

The additional seam constructions that simply rely on glue for bonding include Reinforced Lap Seam Flange, Reinforced Lap Seam, Double Reinforced Lap Seam, and Double Reinforced Butt Seam. PVC, TPU, vinyl, and Hypalon/CSM can all be sewn together using these techniques. Due to the material's incompatibility with heat welding, Hypalon/CSM boats tend to use these methods of seam building more frequently.

3) Reinforced lap seam flanges are no longer frequently, if ever, employed. Especially for life rafts, this seam design was typical for earlier boats. This seam is simple to construct and reasonably sturdy, but the flange makes it susceptible to wear and tear. It is a perfect fit for a one-time use application because of this.

4) Another sturdy seam construction for Hypalon/CSM inflatables is a Reinforced Lap Seam. Because installation can be done by hand, it is frequently employed with less priced boats, although it is prone to wicking and can interfere with quality control.

5) The strongest seams for Hypalon/CSM and the ones that don't wick are double reinforced lap seams. However, only the best inflatables can afford to create these because they are so expensive.

6) For Hypalon/CSM boats, Double Reinforced Butt Seams are the second-best structure. They offer a completed surface that is smooth and aesthetically beautiful and are nearly as sturdy and pricey.

MANY AIR CHAMBERS (INTERNAL BAFFLES): The original inflatables were frequently made from a single tube. This created significant issues because, in the event that the chamber ruptured or punctured, the entire inflatable could be lost, putting everyone on board in peril. Fortunately, designs and manufacturing methods have greatly improved since its conception, with noticeable increases in performance, shape, and safety. At the time of their invention, it was quite challenging to create an inflatable with many tubes and air chambers. Any modern, high-quality inflatable will have numerous air chambers so that, in the case of a tube failure, it may still float and function.

Today, any high-quality inflatable will have numerous air chambers so that it can still float and function if a tube fails. Typically, one tube or a tube inside a tube is used to create pool floats and toy boats like those offered by Intex and Sevylor. Their low price and short lifespan can be attributed in part to their insufficient safety architecture. Luckily, these inflatables are not being utilized too far from land or a place of safety because if the one chamber fails, the entire boat will sink.

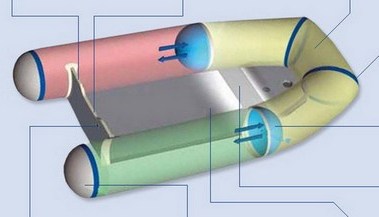

Although some RIBs use this construction, "Soft Tails," or roll-up slat floors, are more common on two chamber inflatables. The chambers can be arranged either bow to stern or side by side. Side by side is superior to bow-to-stern if you have a motor on the back, but it's still not the best option because your motor could be lost if the stern tube were to break. To avoid this, RIBs are frequently built with side-by-side tubes, but it should be noted that two-chambered inflatables are less secure than three-chambered boats. Due to the greater seaworthiness and passenger safety provided by three chambered inflatables, Saturn Boats designs and builds all of its boats with a minimum of three chambers.

The most popular styles of inflatable tenders and RIBs on the market have three chamber construction. Your gas or electric outboard engine will remain above water even if one chamber fails by installing chambers in both tail tubes and the bow as well as one in the stern.

Some larger sport tenders and RIBs use more chambers, but they are less common. Some boats exceeding 12 feet in length have four compartments. Due to their complexity and size, larger boats will cost more than other boats in their class. Although they may appear like decent security to have, they are built this way out of a need for materials rather than out of concern for safety. Three chamber inflatables are a perfect balance between safety and performance because it is extremely unlikely that more than one chamber will fail at once, much alone several.

The baffle will be forced to push into the damaged tube if there is a leak in one tube due to the difference in pressure. A baffle extending into each interior chamber divides them, helping to balance the pressure. The baffle will be forced to push into the damaged tube if there is a leak in one tube due to the difference in pressure. The pressure will therefore decrease from 3.6 psi in each tube and equalize at 1.8 psi when one tube punctures. As the damaged tube loses air, this will assist in balancing the pressure inside of it.As the baffle pulls into the damaged tube and expands, it will also provide buoyancy to the tubes that have not been damaged. Boats with numerous chambers almost always feature internal baffles for safety reasons.

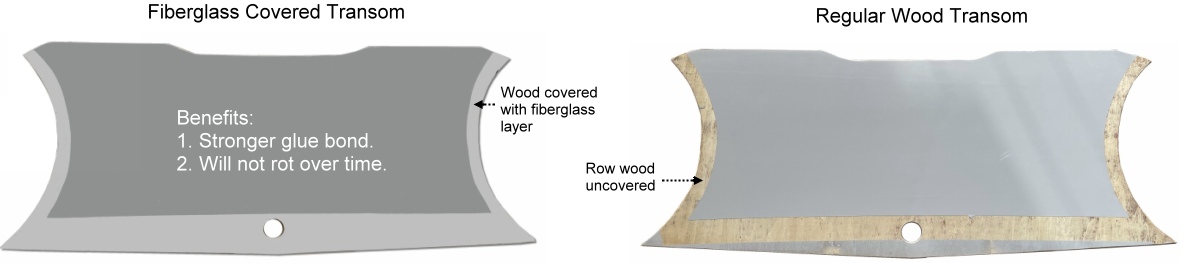

TYPES OF TRANSOM: The transom mount on an inflatable boat is a crucial component. The kind of hardware and power that can be mounted on an inflatable depends on the type of transom. There are two types of transoms: soft transoms and hard transoms. They are really different and can affect how much you can use your inflatable.

SATURN inflatables offers durable inflatable boats with transom covered with fiberglass on both sides. That improve transom longevity and prevent wood from rotting over time.

A soft transom inflatable boat is primarily made to be rowed. After consumers grew weary of utilizing oars as their main form of propulsion, producers developed an auxiliary add-on transom, giving rise to the term "soft transom." Since these mounts are not a part of the boat's actual construction, they cannot support anything weighing more than 30 pounds, which restricts their application to electric trolling motors. These are frequently built of plastic and aluminum, making them relatively light while still being able to support a trolling motor. 'Zodiac boats' never have soft transoms, which are typically found on toy boats.

Fundamentally, an inflatable with a soft transom is made to be rowed. Users got sick of using oars as their main form of propulsion, therefore producers produced an optional add-on transom, which is when the phrase "soft transom" was first used. These attachments are only suitable for electric trolling motors because they are not integrated into the boat's frame and cannot support loads greater than 30 pounds. These are frequently constructed from plastic and aluminum, which allows them to be very light while still being sturdy enough to support a trolling motor. Soft transoms are typically found on toy boats; they are almost never found on "zodiac boats."

POWER OPTIONS: An inflatable boat can be propelled in a number of ways. The type of inflatable application you have in mind and the boat you plan to buy will determine the best method. Oars, sails, trolling motors, jet propulsion motors, gas and electric outboard motors, and other propulsion devices are frequently utilized. This section will discuss the many sorts of thrust-generating techniques and which technique pairs best with which inflatable.

The original modes of propulsion used by boats were sails and oars, which are still in use today. Oars give strength, flexibility, and backup power in an emergency. Oars demand more work than sails, which are quieter, more efficient, and use an additional power source. Both can be utilized as a major source of propulsion as well as auxiliary power in the event that the main engines fail.

All inflatables have oars as an extra power source since they can save your life in the event that your main engine fails. On smaller and lighter inflatables, they can be utilized as the main source of power because they are often strong and difficult to destroy. Oars' obvious drawback is that they require manual labor to operate. The efficiency of them depends on the user's skill and strength. Ours can be used with little "zodiac style boats," soft tails, and playboats. The user choose if oars are the only means of transportation.

All inflatables have oars as an extra power source since they can save your life in the event that your main engine fails. A few inflatable brand names now provide an inflatable sailboat and even a sail kit due to high consumer demand in the market. Despite modern technology, many individuals still find sailing to be a relaxing and enjoyable hobby.

Wind-powered sails will offer environmentally friendly mobility. For those who would prefer to spend less on motor maintenance, this is advantageous. Using sails could be your calling card if you adore sailing. While regular modifications are necessary when operating a sail, they are not as necessary as when rowing. This makes it a more effective choice than using oars. However, operating a sail does take a certain level of expertise and knowledge. Sails can be more prone to tearing and can only be used during windy periods of the day, which are other drawbacks.

For inflatables intended for usage in windy areas like bays or larger lakes, sails can be the perfect option. They would also make a fantastic choice for an ocean traveler looking to cut costs on fuel. All of this is presuming that you know how to sail or operate a sailboat.

Wind-powered sails will offer environmentally friendly mobility. For those who would prefer to spend less on motor maintenance, this is advantageous. Using sails could be your calling card if you adore sailing. While regular modifications are necessary when operating a sail, they are not as necessary as when rowing. This makes it a more effective choice than using oars. However, operating a sail does take a certain level of expertise and knowledge. Sails can be more prone to tearing and can only be used during windy periods of the day, which are other drawbacks.

For inflatables intended for usage in windy areas like bays or larger lakes, sails can be the perfect option. They would also make a fantastic choice for an ocean traveler looking to cut costs on fuel. All of this is presuming that you know how to sail or operate a sailboat.

GAS OUTBOARDS: Since their introduction in the early 1900s, gas engines for boats have been popular. They are the most typical power source for the majority of boats on the market today. Outboard motors were the first commercially available motors that made it possible for a person to have portable power for their boats; they have a reduced initial cost, are simple to maintain, and come in a variety of motor sizes. Any novice boater would be wise to choose one of the competitively priced used gasoline outboard motors.

Outboard motors were the first commercially available motors that made it possible for a person to have portable power for their boats; they have a reduced initial cost, are simple to maintain, and come in a variety of motor sizes. The majority of boaters find outboards to be a convenient alternative because almost every marina or lake town has a local mechanic who can quickly service gas outboards. With electric and jet propulsion motors, however, which require more specialized experience and knowledge to repair, this is far from the truth. Additionally, gas engines are created in a variety of sizes, meeting the needs of everyone. One of the main advantages of buying a gas outboard is the comfort that comes from familiarity when running one for the first time.

Electric boats: Electric outboard motors are becoming more and more commonplace on the market as a result of improvements in energy storage and component design. To meet the needs of those who want a reliable, quiet, and energy-free motor, this industry is continuously expanding. Electric motors' excellent silent operation enables users to take in their surroundings without having to endure the constant noise of a gas engine. Depending on how you charge the battery, their capacity to operate on "cleaner" energy influences the size of your carbon footprint, making them a desirable option for some users.

Although owning an electric engine has advantages, electric outboards can have drawbacks. Electric motors can cost more than twice as much as their gas outboard counterpart, therefore the initial investment in equipment is significantly greater than that required for gasoline-powered motors. This excludes the price of purchasing the batteries required for use in order to store electricity. The batteries required to power these motors can be costly, labor-intensive to charge, and quickly depleted. This indicates that the run time of the motor will only be minimally increased even if you have a solar power charger while it is operating. These factors reduce the usefulness of such motors for long-distance travel or equipment transfer. In light of these aspects, electric engines are a brilliant idea, but additional technological advancements in terms of efficiency, dependability, and cost efficiency are required to make them an appealing alternative for everyone. These motors might be practical for people with big starting budgets, but they are prohibitively expensive for many sailors.

Electric trolling motors are comparable to electric outboard motors but are categorized differently. They are essentially distinct from outboards because they are not meant to be a boat's main source of propulsion. However, many people still utilize electric outboards as their main source of propulsion because of their similarities in terms of quality and advantages. Because of its quiet operation, low price, and ability to keep a boat in one place, trolling motors are quite used in the fishing industry. Because to their small weight and few moving parts, trolling motors are also incredibly portable and simple to install by one person.Trolling motors are used by many sailors as well. Sailors value trolling motors' low cost, ability to move at slow speeds, and silent operation for navigating in and out of slips, marinas, and harbors.

Trolling motors are comparable to electric outboards in construction and design, however they are utilized more as a backup power source. As a result, they are usually constructed with lower thrust ratings and produce no more than 3 hp equivalent. It is not recommended to use a trolling motor while the main engine is running.

The projected weight of a boat and the intended use of the boat will determine whether a trolling motor is appropriate for you. For soft tail inflatables and some smaller sport boats, trolling motors make excellent primary motors. The projected weight of a boat and the intended use of the boat will determine whether a trolling motor is appropriate for you. A gas or electric outboard is advised if speed is your main concern. Trolling motors work best when used as a secondary or supplemental source of power or for brief, leisurely excursions on calm waters.

Applications for inflatable boats:

The most adaptable boats on the market are inflatable ones. There is little doubt that these boats can be employed in practically any situation due to their small size, lightweight design, and ability to carry many times their own weight. In the sections that follow, we'll go over some of the most popular applications for inflatable boats as well as how they compare to other types of watercraft.

For yacht or sailboat owners who require a ship to shore boat but have limited storage space, inflatable zodiac boats are fantastic. Sport boats' modest storage spaces and portability, while yet providing high performance and entertainment, provided a solution to this issue. The perfect inflatable is made up of all these outstanding characteristics, and boat enthusiasts rarely forget it.

With hard floor tenders, your only concerns should be the weight of the inflatable and the small amount of storage space the floor pieces take up. The enhanced rigidity of a hard floor allows for more stable planning speeds and remarkable floor durability for large loads and choppy waters. This eliminates the worry that you'll scratch your yacht or sailboat's floor when carrying a range of stuff there and back.

Roll-ups are as portable as air flooring, but they also have certain additional advantages over hard floors. A excellent option for sailboats, air flooring offer the ability to take off, directional stability, and less weight than hard floors. This makes it possible to transport them aboard and assemble and disassemble them quickly. Users who find wood and aluminum floors to be too rigid or unforgiving may also find comfort in the softer, more cushioned air floors. Although air floors are fantastic, they don't provide the same performance or longevity as hard floors. When cutting through large wakes and waves, they become less stable because they are more flexible and bendable. Though air floors are constructed from the same sturdy material as inflatables, it is still advisable to keep sharp or abrasive things off the floor.

Sport boats also make very economical runabouts because they offer outstanding performance on the water and take up less space when set up and taken down. Sport boats are the ideal choice for this application because a runabout boat is a personal watercraft used for quick, brief outings.

Boaters who travel, have limited storage room at home, or keep their boat at the dock but don't want to pay the high maintenance costs associated with a solid hull boat may consider inflatable boats. The sports tender is the ideal option for RV campers, apartment residents, and many people who prefer to rent a locker at their local marina. They can be inflated and put together in less than 15 minutes by one person, or even quicker with two. You can board a plane thanks to the inflatable keel, which also provides directional stability, speed, and performance to bring you to your goal.The performance of inflatable boats across the board, rather than any particular characteristic, is what makes them excellent runabouts. As a result, almost any of our boats may make the ideal runabout.

Fishing: Sport boats' adaptability makes them suitable as small, personal fishing vessels, and their toughness and buoyancy make them excellent choices for both fresh and saltwater. They are effective personal fishing vessel thanks to their big tubes and keel. You may cast and stand anywhere on an inflatable boat without it shaking or upsetting the balance of the other passengers because to its unmatched stability. Hard floors are recommended but not necessary for fishing due to the use of hooks, fillet knives, and other equipment. The 1100 Denier German PVC material used to construct Saturn boats is incredibly durable and is also utilized to construct numerous whitewater or fishing rafts. When inflated properly, there shouldn't be any worry about hooks piercing the material without exerting a lot of power. Sports tenders are able to steer you into shallow water because they don't have a deep-V and instead have an inflatable keel.With a maximum load capacity that is around 10 times their own weight, service members may concentrate more on the operation or goal at hand and less on their equipment. Users can quickly assemble or disassemble the boat because to its short inflation and deflation times, which is ideal for quickly exiting the sea and vanishing without a trace.

RESEARCH BOAT: Sports Tenders are excellent choices for many excursions and researchers. Typically employed as tenders for larger boats, they can also be launched from land to reach distant sites. PVC inflatables are more affordable than other inflatables or personal watercraft, which makes them suitable for many research projects' limited budgets. This enables research funds to be allocated to the research itself rather than pricy machinery. They can be easily managed by a small workforce and have more space for equipment thanks to their portability. They are ideal for researchers conducting experiments in varied habitats because of their resistance to abuse and harsh conditions. Anywhere—ocean, lake, pond, river, marsh—a Saturn inflatable boat will always operate at its peak. The right vessel and size will be chosen based on the type of research being conducted as well as the personnel and equipment that will be employed. Please give us a call if you need help selecting the ideal boat for your needs.

DIVE BOAT: Inflatables make excellent dive boats for spearfishing, freediving, snorkeling, and scuba diving. All of the tubes on dive inflatables include grab ropes, making it simple to enter and depart for diving. By simply rolling backward, you can easily deploy your equipment into the water after preparing it in the huge tubes. Large, stable tubes prevent your boat from rocking when you shift the weight to one side of the boat, and they also make getting back in the boat simple. Again, we advise a hard floor for this kind of application due to the usage of heavy and potentially sharp equipment. A hard surface would be more suited for the potential abuse given the range of gear that divers may possess.As dive boats, we suggest our larger boat types, the Baja and Catalina. The bigger area will be able to offer enough room for supplies, equipment, and preparation.

UTILITY BOAT: When shifting weight to one side of the boat, large stable tubes keep the boat from rocking and make getting back in the boat a snap. If it wasn't obvious, sports tenders are quite adaptable and can be used in practically any situation. Weekend warriors may use them thanks to their extraordinary portability, their performance and durability are ideal for many uses, and their stability keeps users safe in a range of environments. They can be further divided into hard floors and air floors, which helps to increase the variety of users for whom they are helpful. You may utilize a sport tender for just about any circumstance.

ROW BOATS: Some people still use rowboats as a traditional form of tender. If properly maintained, they can last for a very long time and are often composed of wood, plastic, or fiberglass. However, because they have a solid hull, they are difficult to store and remove from the water, necessitating the use of a davit or long-term towing arrangement. Another drawback of these solid-hulled boats is that if you let them drift against your yacht, the pricey paint will be soon marked up and damaged. A rowboat's main drawback is that it needs to be powered by hand. You cannot place a motor on the transom to move from Point A to Point B.

DRIFT BOATS: Drift boats are made to be used for fishing in rivers and streams. They feature thin pointed sides, flaring sides, and broad flat bottoms. For small, shallow streams where regular boats would likely bottom out, this makes a wonderful fishing boat. Additionally very adaptable and customizable, these boats. The majority of businesses make their seats detachable and offer extras that can be customized to your preferences and needs. The most common method of propulsion for these boats is using oars, however an outboard motor is also an option. These, however, are poor choices for yacht tenders.It would be an extremely uncomfortable ride out in the ocean because of the flat bottom design, which causes them to ride on top of the waves and chop rather than cutting through it. Because they are composed of fiberglass or aluminum, these boats are heavier overall and less portable. This necessitates either towing them or mounting them on a davits system.

JON BOATS: Jon boats are well-known for their use in fishing. They have a flat bottom, similar to Drift Boats, which enables users to enter the shallow water without bottoming out. They are typically less priced, built of fiberglass, wood, or aluminum, and relatively simple to maintain. Additionally, they have a transom that can house an outboard motor to propel your boat. Since a Jon Boat is still very light, it may travel at great speeds as it planes over the water. They are not made to manage choppy waves, though, as they are flat and only float on top of the water.The Jon Boat is a less adaptable option for a Yacht Tender because it won't be able to perform effectively in the broad ocean while being quite affordable, simple to maintain, and reasonably light.